Korean SME Emerges as Runner-up for the 2026 Zayed Prize for Sustainability in Abu Dhabi

2026-02-02

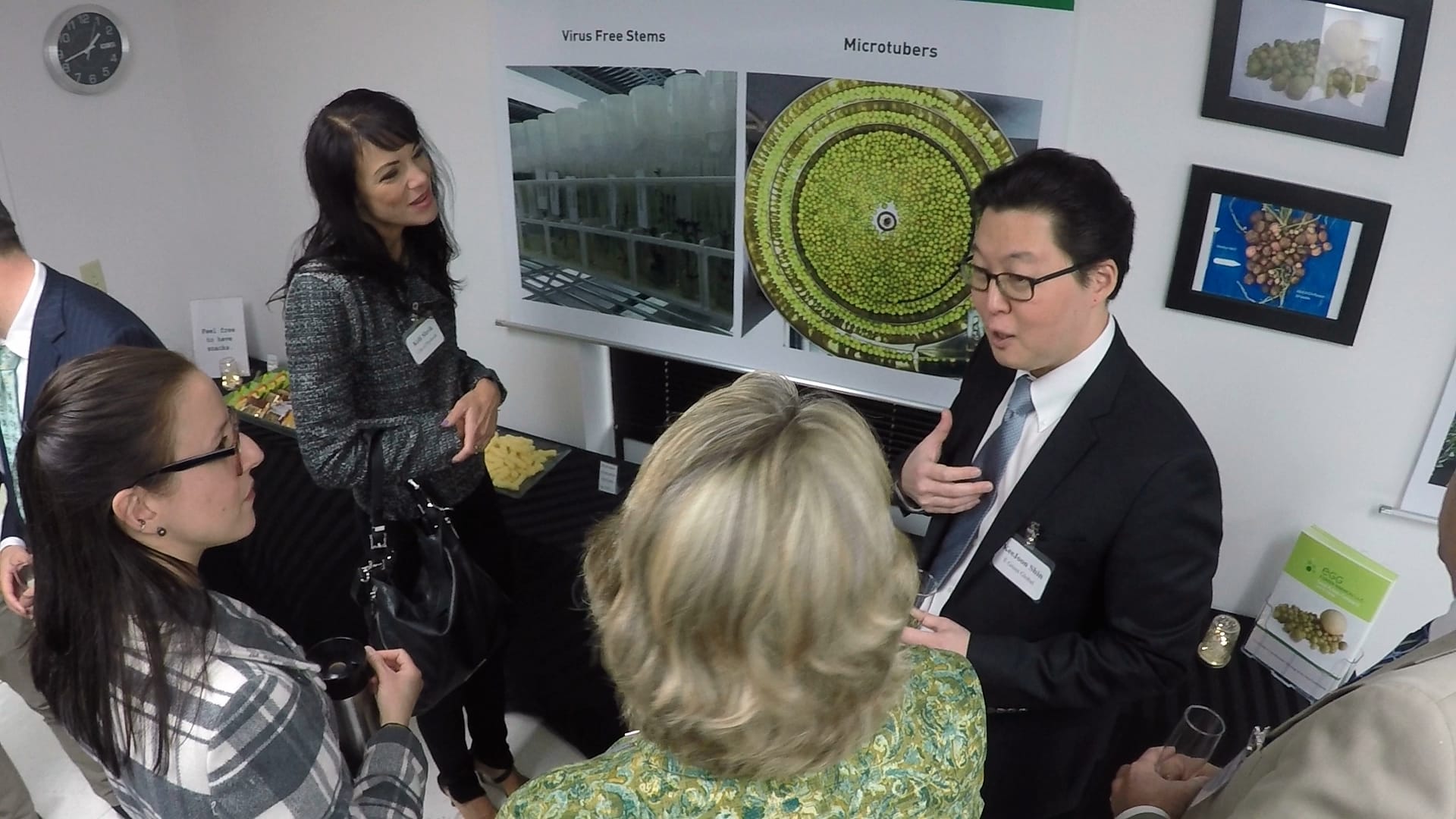

E Green Global, an SME from Korea, has emerged runner-up for the 2026 Zayed Sustainability Prize award (under the Finalist Food category), which happened at the Abu Dhabi Sustainability Week in Abu Dhabi from January 13-15, 2025.

According to studies from the Food and Agriculture Organization (FAO) and the International Potato Center, potatoes are the 4th largest crop in the world by production and the 3rd largest by human consumption, and one man, Keejoon Shin, is expanding quality seed production in Korea, the USA, China, Saudi Arabia, and the Netherlands.

The microtuber technology (MCT) of E Green Global produces disease-free seed potatoes in indoor plant factories, benefiting 15 million people and distributing over 10 million seed potatoes annually. Alongside popular demand, potatoes are frequently used as French fries by global restaurant giants such as McDonald's and Burger King, among others, to deliver fast food to corporate and local communities.

During Abu Dhabi Sustainability Week, I interviewed the CEO of E Green Global, Keejoon Shin (PotatoEurope 2021 Innovation Award – Gold), to get key insights on his innovation that is boosting food security, reducing carbon (CO2) emissions, and advancing Korea's green, smart technologies for the world.

The interview took place on Thursday, January 14th, 2025, through Microsoft Teams

How did you start your potato business and why?

There's a huge demand for potato seeds in the world, but it is difficult to get high-value potatoes, because only 20% are considered good quality, with 80% bad seeds. In addition, there is only one system in the world, which is expensive, utilizes a lot of greenhouse gases, and takes a lot of time to supply.

I started my company in 2009 and teamed up with 2 incredible scientists, and we chose potatoes as the first product to make through microtuber technology without a greenhouse.

We are making this inside a lab through a light system, and eliminating the greenhouse. As a result, we produced high-quality seeds, lowered the cost, less chemicals and water, reduced land space, and reduced delivery time. We are supplying more high-quality seeds to farmers. Which means that with us, farmers can have more access to good seeds that can increase their yields and income. We are using few resources to achieve this, and this is why our process is sustainable.

How do you feel about being recognized by the Zayed Prize Award?

I am excited about the prize and the fact that we were recognized. But first, let me give you a background on why this award means a lot to me. Around 160 countries produce potatoes globally, including in Africa. However, MENA East and South West Asia don't have good seeds and need to import or set up a local system. Currently, importing is expensive. It is $500 per tonne and $500 per shipping with little storage time. Which is too expensive for farmers.

We set up a joint collaboration with Saudi Arabia using our localised technology. We can replace all imported seeds because we want Saudi Arabia to be self-sufficient with potatoes. Which leads to food security and sovereignty, and maybe in the future they can export. This is a closed-door type of industry, and many people don't know except potato companies and farmers. And it is great to have been picked.

As you scale across regions with different climates, cultures, and supply chains, what are the biggest challenges you’ve faced, and how do you ensure quality without compromising sustainability and affordability?

There are pros and cons. After the COVID pandemic and the Russia-Ukraine war, potatoes were ordered but did not arrive due to geopolitical issues. This affected farmers' income.

What we want to do is go to 160 countries and set up a local potato system working with governments, local people, and companies. We have to go through market validation. We are recognized in China and Europe and are now commercialized. In 2022, we signed an MOU with Bonghwa (a local government in Korea), and in 2015, an MOU for a JV setup with Xingye, China, and a production facility setup in Saudi Arabia.

Meanwhile, in 2022, we raised 7.6 billion KRW in investment for our subsidiary E Green Europe B.V. to boost direct-to-field quality seed production while maintaining cost-friendly rates.

Our goal currently is to work with governments, the MENA region, and next Africa

How about this article?

- Like1

- Support0

- Amazing0

- Sad0

- Curious0

- Insightful0